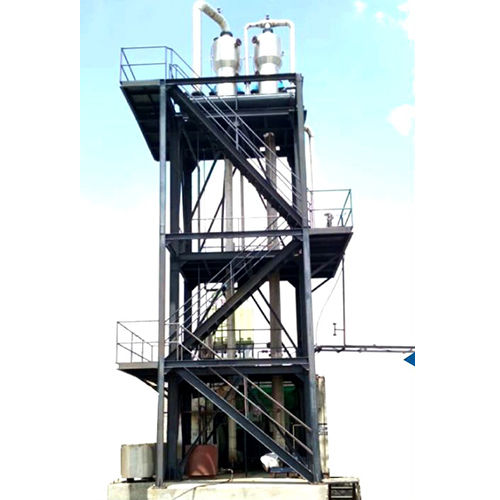

Multiple Effect Evaporator

Product Details:

- Usage Industrial

- Condition New

- Power Source Electric

- Product Type Multiple Effect Evaporator

- Material Metal

- Warranty 1 Years

- Click to View more

X

Multiple Effect Evaporator Price And Quantity

- 1 Unit

Multiple Effect Evaporator Product Specifications

- Industrial

- Multiple Effect Evaporator

- Electric

- New

- Metal

- 1 Years

Multiple Effect Evaporator Trade Information

- Cash Advance (CA)

- 10 Unit Per Week

- 30 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

A Multiple Effect Evaporator (MEE) is an industrial apparatus designed to efficiently concentrate solutions, typically by removing water. This device is widely used in industries such as food processing, pharmaceuticals, chemicals, and wastewater treatment. Heres a detailed overview of its working principle, components, and advantages:

Working Principle

The basic working principle of a multiple effect evaporator is to use the steam produced from one effect (stage) as the heating medium for the next effect, thereby conserving energy and reducing operational costs. The process involves several stages (or effects), where each subsequent effect operates at a lower pressure and temperature than the previous one. This allows for efficient use of the energy contained in the steam.

- First Effect: The feed solution is introduced and heated using steam. The boiling process produces vapor, which contains most of the solvent (typically water) and a concentrated solution.

- Second Effect: The vapor produced in the first effect is used as the heating medium for the second effect. Since the second effect operates at a lower pressure, the vapor condenses, releasing its latent heat and causing the solution in the second effect to boil and produce more vapor.

- Subsequent Effects: This process continues across multiple effects, each operating at progressively lower pressures and temperatures. The number of effects can vary, typically ranging from two to seven or more, depending on the application and desired efficiency.

Components

- Heat Exchangers: These are used in each effect to transfer heat from the vapor to the solution.

- Condensers: They condense the vapor into a liquid, usually after the last effect, to recover water or other solvents.

- Pumps: These are necessary to move the solution through different stages and maintain the desired flow rates.

- Vacuum System: To maintain the lower pressures required in the subsequent effects.

- Feed and Product Tanks: For storing the incoming solution and the concentrated product.

- Piping and Valves: For controlling the flow and pressure throughout the system.

Advantages

- Energy Efficiency: By reusing the vapor from one effect as the heating medium for the next, the MEE significantly reduces steam consumption compared to single-effect evaporators.

- Operational Cost Reduction: Lower steam consumption translates to lower fuel costs, making the process economically favorable.

- Scalability: MEEs can be designed with multiple effects, allowing for customization based on the required concentration levels and production capacities.

- Environmentally Friendly: Reduced energy usage means a smaller carbon footprint, making it a more sustainable option.

Applications

- Food and Beverage Industry: Concentrating juices, milk, and other liquid food products.

- Pharmaceutical Industry: Producing concentrated solutions of active ingredients.

- Chemical Industry: Concentrating chemicals and recovering solvents.

- Wastewater Treatment: Reducing the volume of wastewater by removing excess water.

Conclusion

Multiple Effect Evaporators are essential in industries requiring the concentration of solutions. Their design allows for significant energy savings and operational efficiencies, making them a preferred choice for large-scale evaporation processes. The principle of reusing heat energy through multiple stages highlights the ingenuity in industrial process design aimed at sustainability and cost-effectiveness.

FAQs of Multiple Effect Evaporator:

Q: What is the warranty period for the Multiple Effect Evaporator?

A: The warranty period for the Multiple Effect Evaporator is 1 year.Q: What is the power source for the Multiple Effect Evaporator?

A: The power source for the Multiple Effect Evaporator is electric.Q: What is the material used in the construction of the Multiple Effect Evaporator?

A: The material used in the construction of the Multiple Effect Evaporator is metal.Q: What is the intended usage of the Multiple Effect Evaporator?

A: The intended usage of the Multiple Effect Evaporator is industrial.Q: Is the Multiple Effect Evaporator a new product?

A: Yes, the Multiple Effect Evaporator is a new product.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free